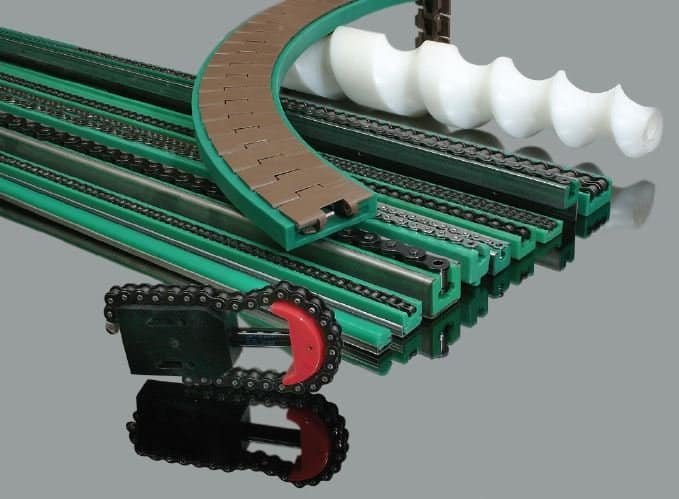

UHMWPE friction strips are strips or tapes made of ultra-high molecular weight polyethylene (UHMWPE) that are used to reduce friction between two surfaces. These strips can be applied to a wide range of surfaces, including conveyor belts, chutes, and guide rails, to reduce wear and tear and increase efficiency.

UHMWPE friction strips have a low coefficient of friction, which means that they have a high resistance to sliding and reduce the force required to move products along a surface. This makes them ideal for use in the food industry, where they can help to reduce energy costs and increase production efficiency.

UHMWPE friction strips are also resistant to chemicals, moisture, and abrasion, which makes them suitable for use in harsh environments commonly found in the food industry. They are easy to install and can be cut to the required length, making them a cost-effective solution for reducing friction and extending the lifespan of equipment.

In summary, UHMWPE friction strips are a useful tool for reducing friction between surfaces in the food industry. Their low coefficient of friction, resistance to chemicals and abrasion, and ease of installation make them an ideal choice for increasing efficiency and reducing wear and tear on equipment.