Polyetheretherketone, commonly known as PEEK, is a high-performance thermoplastic that has revolutionized the engineering and manufacturing industries. Its unique combination of properties makes it an ideal choice for a variety of applications, particularly those requiring high strength, stiffness, and temperature resistance.

In this ultimate article, we will take a closer look at PEEK, including its properties, applications, and processing methods.

Properties of PEEK

PEEK is a member of the polyaryletherketone (PAEK) family, which also includes other high-performance plastics like polyetherketone (PEK) and polyetherketoneketone (PEKK). PEEK’s unique combination of mechanical, thermal, and chemical properties makes it an excellent choice for a wide range of applications. Here are some of the key properties of PEEK:

- High Temperature Resistance: PEEK is known for its excellent high-temperature resistance, with a glass transition temperature (Tg) of around 143°C and a melting temperature (Tm) of around 343°C. This makes it suitable for applications that require exposure to high temperatures, such as aerospace, automotive, and electronics.

- High Mechanical Strength: PEEK has a high mechanical strength, including high stiffness and toughness, which makes it ideal for applications that require high strength-to-weight ratios. It also has excellent resistance to fatigue and creep.

- Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, including acids, bases, and organic solvents. It is also resistant to radiation, which makes it ideal for applications in nuclear and medical industries.

- Low Friction Coefficient: PEEK has a low coefficient of friction, which makes it ideal for applications where low friction is necessary, such as in bearings, gears, and other moving parts.

- Excellent Electrical Properties: PEEK has excellent electrical properties, including a high dielectric strength, low dielectric constant, and low dissipation factor, which makes it ideal for electrical and electronic applications.

Applications of PEEK

PEEK’s unique combination of properties has made it an ideal material for a variety of applications in various industries. Here are some of the common applications of PEEK:

- Aerospace: PEEK is used in the aerospace industry for its high temperature resistance, low weight, and excellent mechanical properties. It is used in various parts of aircraft, such as bearings, gears, and seals.

- Automotive: PEEK is used in the automotive industry for its high temperature resistance, low friction, and excellent wear properties. It is used in various parts of the car, such as bearings, gears, and seals.

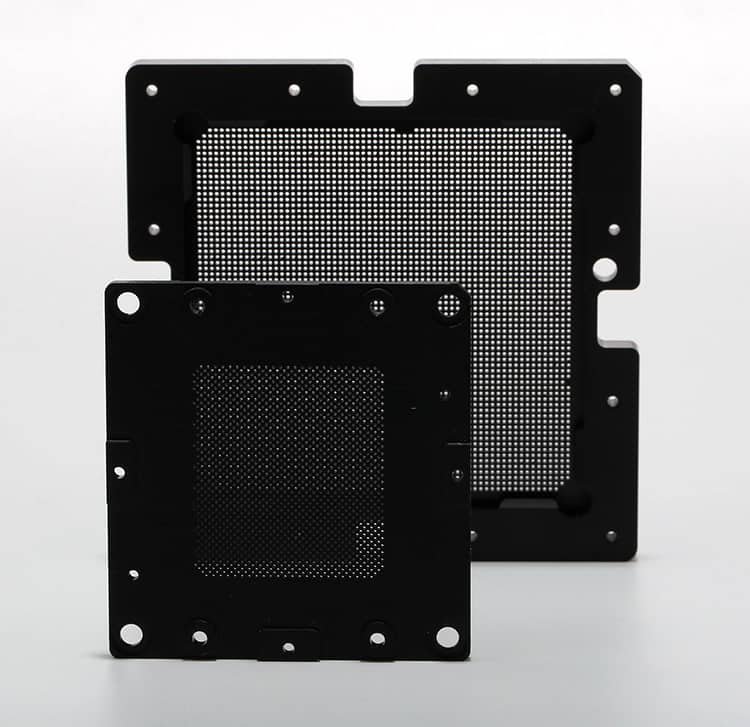

- Electronics: PEEK is used in the electronics industry for its excellent electrical properties, high temperature resistance, and chemical resistance. It is used in various electronic components, such as connectors, switches, and insulators.

- Medical: PEEK is used in the medical industry for its biocompatibility, high strength, and excellent wear properties. It is used in various medical devices, such as orthopedic implants, dental implants, and spinal implants.

- Oil and Gas: PEEK is used in the oil and gas industry for its high temperature and pressure resistance, as well as its excellent chemical resistance. It is used in various parts of the oil and gas production equipment, such as valves, pumps, and seals.

Processing Methods of PEEK

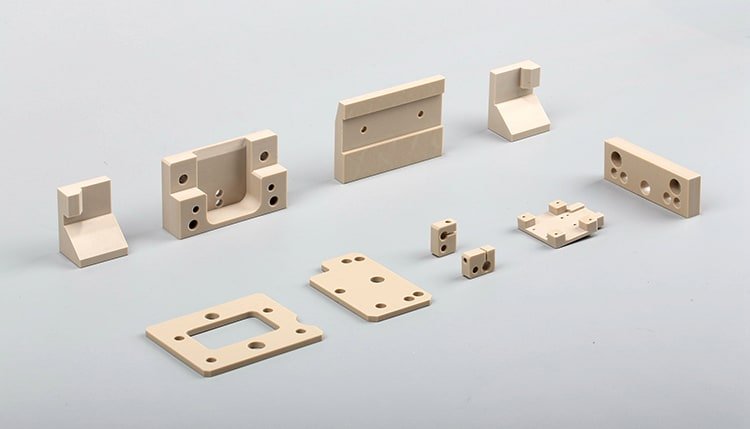

PEEK is a high-performance thermoplastic that can be processed using various methods. Here are some of the common processing methods of PEEK:

- Injection Molding: Injection molding is the most common method of processing PEEK. It involves melting the PEEK pellets and injecting them into a mold cavity. The mold is then cooled, and the part is ejected.

- Extrusion: Extrusion is another common method of processing PEEK. It involves melting the PEEK pellets and forcing them through a die to create a continuous profile, such as a rod, tube, or sheet.

- Compression Molding: Compression molding is a method of processing PEEK that involves compressing the PEEK powder into a mold cavity at high temperature and pressure. The mold is then cooled, and the part is ejected.

- Machining: PEEK can also be machined using conventional machining methods, such as milling, turning, and drilling. However, due to its high temperature resistance, special tools and techniques are often required to machine PEEK.

- 3D Printing: PEEK can also be 3D printed using various methods, such as Fused Filament Fabrication (FFF) and Selective Laser Sintering (SLS). 3D printing allows for the creation of complex geometries that would be difficult to achieve using other methods.

PEEK Grades and Properties

PEEK is available in various grades, each with unique properties and characteristics. Here are some of the common PEEK grades and their properties:

- Unfilled PEEK: Unfilled PEEK is a general-purpose grade of PEEK that has good mechanical properties, chemical resistance, and electrical properties. It is also available in various colors.

- Carbon-Filled PEEK: Carbon-filled PEEK is a grade of PEEK that has enhanced mechanical properties, including higher stiffness and strength. It is often used in high-performance applications.

- Glass-Filled PEEK: Glass-filled PEEK is a grade of PEEK that has enhanced mechanical properties, including higher stiffness, strength, and wear resistance. It is often used in applications that require high wear resistance.

- Bearing Grade PEEK: Bearing grade PEEK is a grade of PEEK that has enhanced wear properties, making it ideal for use in bearing applications.

- Medical Grade PEEK: Medical grade PEEK is a grade of PEEK that has been specifically formulated for use in medical applications. It has excellent biocompatibility and is often used in medical implants.

PEEK is a high-performance thermoplastic that has revolutionized the engineering and manufacturing industries. Its unique combination of properties, including high temperature resistance, high mechanical strength, and chemical resistance, makes it an ideal choice for a wide range of applications, including aerospace, automotive, electronics, medical, and oil and gas.

PEEK can be processed using various methods, including injection molding, extrusion, compression molding, machining, and 3D printing.

PEEK is available in various grades, each with unique properties and characteristics, making it a versatile material for a wide range of applications. With its superior properties and wide range of applications, PEEK is set to play a significant role in the future of engineering and manufacturing.