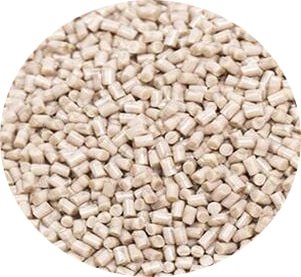

The grades of Gonow PEEK are divided into: glass fibre PEEK, carbon fibre PEEK, anti-static PEEK and conductive PEEK.

PEEK: Polyetheretherketone, which has excellent dielectric properties until temperatures reach 260 degrees. It is also resistant to energy radiation.

Polyetheretherketone is a new type of semi-crystalline aromatic thermoplastic made by condensation of difluorobenzophenone and hydroquinone in the presence of alkali metal carbonates, with diphenyl sulfone as solvent.

It is a high temperature thermoplastic with a high glass transition temperature (153°C) and melting point (342°C) and a load thermal transformation temperature of up to 325°C (30% glass fibre or carbon fibre reinforced grades), and can be used for long periods at 250°C. Compared with other high temperature resistant plastics such as PI, PPS, PTFE and PPO, the upper limit of use temperature is nearly 50°C higher.

Polyetheretherketone resins are not only superior in heat resistance to other high temperature resistant plastics, but also have high strength, high modulus, high fracture toughness and excellent dimensional stability.

Polyetheretherketone resins have greater rigidity, better dimensional stability and a lower coefficient of linear expansion, very close to that of metallic aluminium materials.

Excellent resistance to chemicals, among the usual chemicals, only concentrated sulphuric acid can dissolve or destroy it, and its corrosion resistance is similar to that of nickel steel, while it is itself flame retardant, releasing little smoke and toxic gases under flame conditions and being highly resistant to radiation.

PEEK resin has good toughness and excellent fatigue resistance to alternating stresses, the most outstanding of all plastics and comparable to alloy materials.

Outstanding tribological properties of PEEK resin, with excellent resistance to sliding and micro-motion wear, in particular the ability to maintain high wear resistance and a low coefficient of friction at 250°C.

PEEK resins are easy to extrude and injection mould, with excellent processing properties and high moulding efficiency.

In addition, polyetheretherketone also has excellent properties such as good self-lubrication, easy processing, stable insulation and resistance to hydrolysis. PEEK has excellent overall performance, good mechanical properties, high temperature resistance and superior chemical resistance, making it the most versatile advanced plastic.

Gonow Plastics provides PEEK semi-finished products like PEEK Sheet, PEEK Rod, PEEK Tube and PEEK films, we can also offer CNC Machining service for finished products as customers’requirements.