Polyphenylene sulfide (PPS) is a high-performance engineering plastic that is used in a wide range of applications due to its excellent thermal, mechanical, and chemical properties. In this blog, we will explore the properties and applications of PPS.

Introduction

- Overview of PPS

- History of PPS development

- Properties of PPS

Properties of PPS

- Thermal properties of PPS

- Mechanical properties of PPS

- Chemical resistance of PPS

- Electrical properties of PPS

Applications of PPS

- Automotive industry

- Fuel system components

- Electrical connectors

- Under-the-hood parts

- Aerospace industry

- Electrical and electronic components

- High-temperature seals

- Structural components

- Electrical and electronic industry

- Connectors and sockets

- Circuit board components

- High-temperature insulation

- Industrial and consumer goods

- Pump and valve components

- Household appliances

- Food processing equipment

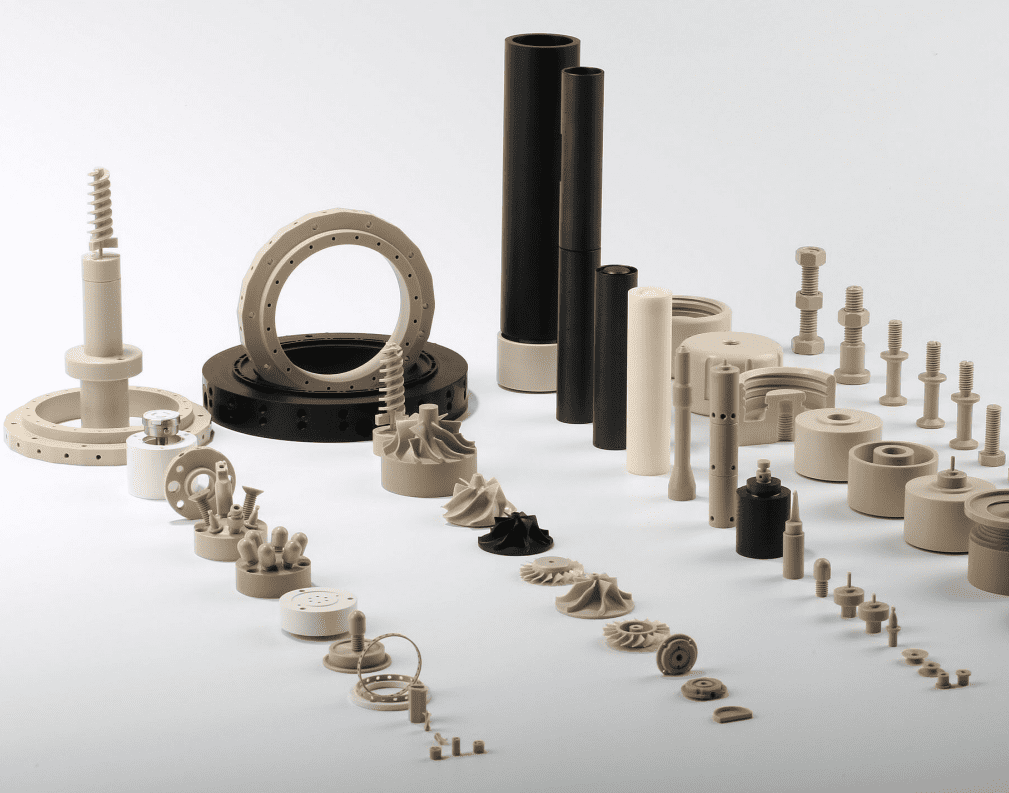

Automotive Industry Applications PPS has been widely adopted by the automotive industry due to its excellent thermal and mechanical properties, as well as its resistance to chemicals and wear.

A. Fuel system components

- Fuel pump impellers

- Fuel injector components

- Fuel filter housings

B. Electrical connectors

- Wire harness connectors

- Sensor connectors

- Battery connectors

C. Under-the-hood parts

- Timing belt covers

- Intake manifolds

- Water pump housings

Aerospace Industry Applications PPS is also used in the aerospace industry for its high-temperature resistance, strength, and lightweight characteristics.

A. Electrical and electronic components

- High-temperature connectors

- Avionics housings

- Circuit board components

B. High-temperature seals

- Gaskets

- O-rings

- Sealing washers

C. Structural components

- Wing flaps

- Control surfaces

- Engine mounts

Electrical and Electronic Industry Applications PPS is used in the electrical and electronic industry due to its high dielectric strength, excellent dimensional stability, and resistance to chemicals and moisture.

A. Connectors and sockets

- High-temperature connectors

- IC sockets

- Relay sockets

B. Circuit board components

- SMT connectors

- Chip carriers

- Socket connectors

C. High-temperature insulation

- Transformers

- Switchgear

- Motors

Industrial and Consumer Goods Applications PPS is used in various industrial and consumer goods applications due to its excellent resistance to chemicals, heat, and wear.

A. Pump and valve components

- Pump impellers

- Valve bodies

- Pump casings

B. Household appliances

- Iron soleplates

- Hair dryer components

- Food processor components

C. Food processing equipment

- Conveyor belts

- Processing trays

- Food chopper components

PPS is a high-performance engineering plastic that is used in a wide range of applications, from automotive and aerospace to electrical and electronic and industrial and consumer goods. Its excellent thermal, mechanical, and chemical properties make it an ideal material for applications that require high-temperature resistance, strength, and durability.