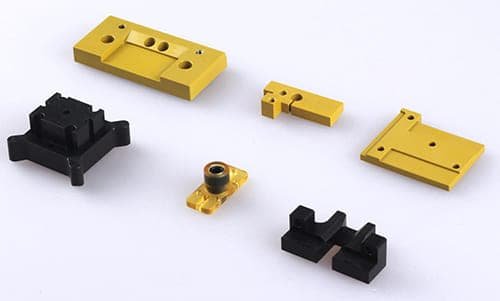

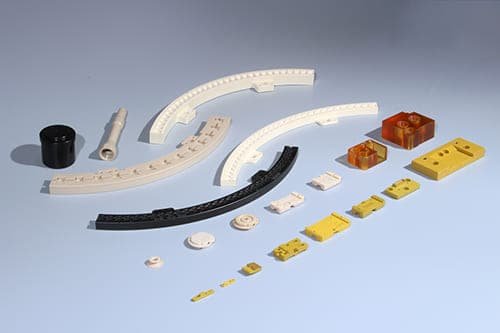

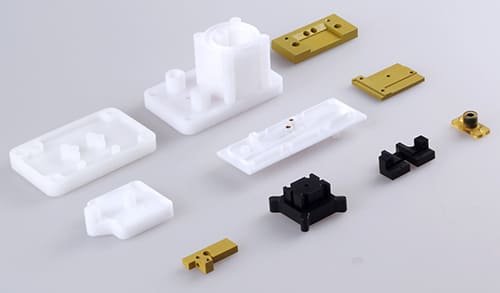

We process the high performance plastic PAI (Polyamide-imide) as semi-finished products in the form of sheets, round rods, and tubes as well as machined components.

Gonow PAI Polyamide-imide The strength of polyamide-imide is incomparable to any industrial unreinforced plastic in the world today, its tensile strength exceeds 172 MPa, and its heat deflection temperature is 274°C under l.8 MPa load.

Polyamide-imide may also undergo solid state polymerization after fabrication to provide improved performance by increasing molecular weight through post-curing. Post-curing occurs at 260°C, and the time and temperature required for curing depends primarily on the thickness and shape of the parts.

It can be used for a long time at 260°C, does not lose weight at 300°C, and starts to decompose at about 450°C.

Its adhesion, flexibility and alkalinity is better.

It can be cured and cross-linked with expoxy resin and has good abrasion resistance.

Polyamide-imide has excellent mechanical properties, and the tensile strength of natural color material is 190 MPa.

Molded plastic is mainly used for gear sticks, bearings and copier separation jaws, etc. It has good ablation resistance and electric under high temperature, high frequency.

It can be used as ablative material, permeable material and structural material for aircraft.

It has good adhesion to metal and other materials. It is suitable for wire enamels, impregnating enamels, films, laminates, coatings and adhesives. For example, Enameled wire made from it has been used in H-class deep-water submersible motors, the laminate is used for printed circuit boards and sockets, and the sea film is used as insulation wrapping material.