UHMW-PE

Chain Guide & Guide Rail & Wear Strip & Support Bar Manufacturer in China

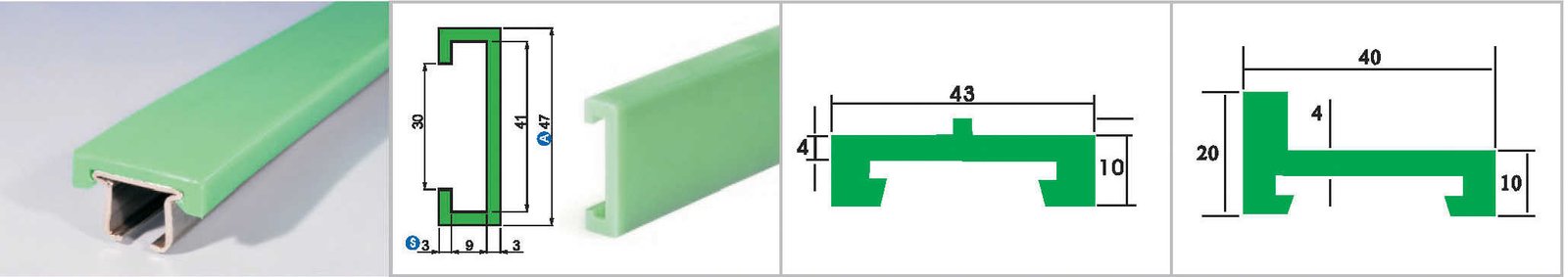

Gonow UHMW-PE Chain Guide

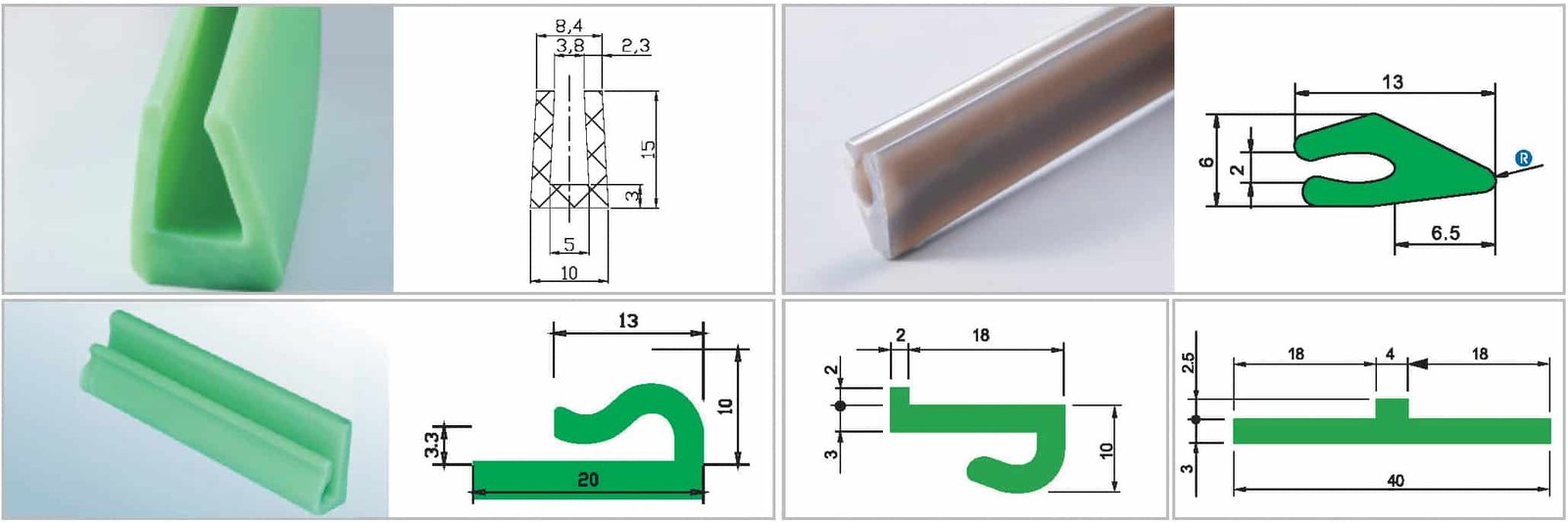

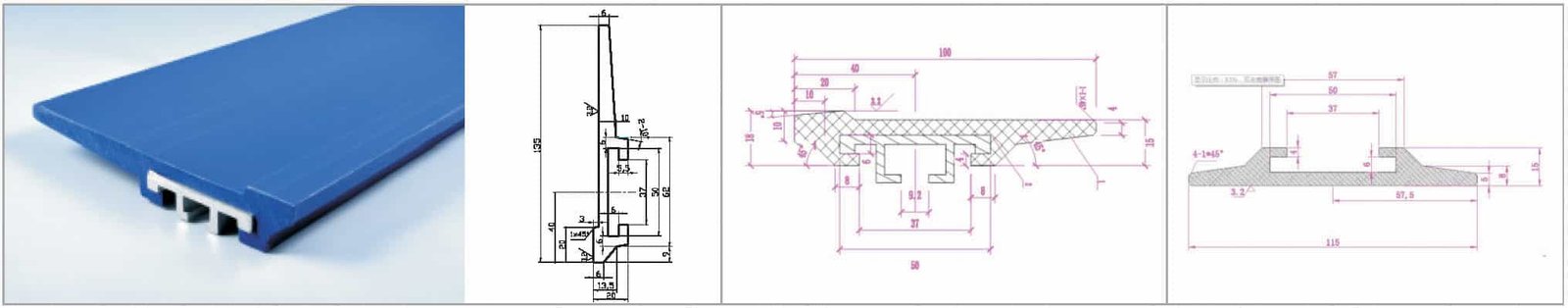

Gonow UHMW-PE Models

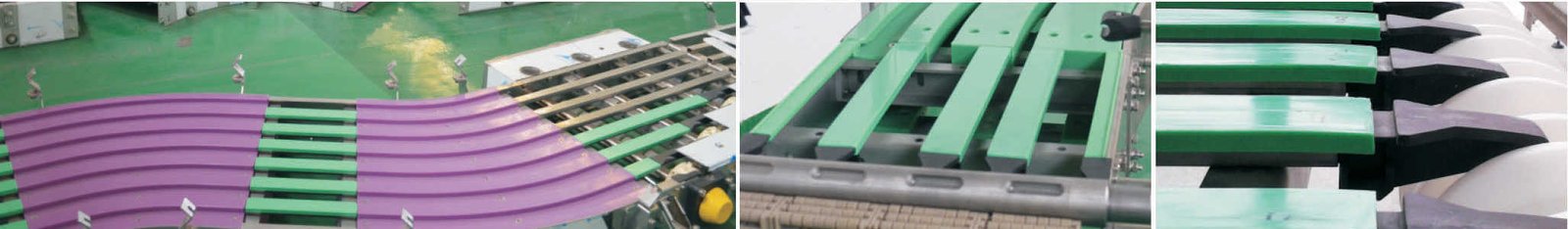

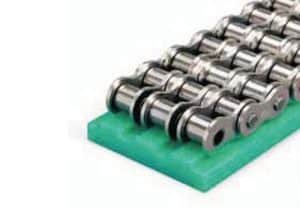

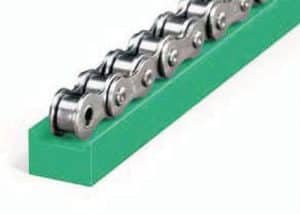

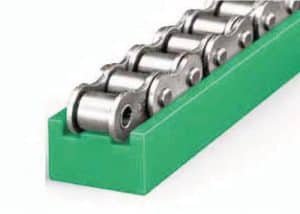

The UHMW chain guide is a kind of hydrostatic guide rail used to support and guide the chain, reduce the friction of the chain, reduce noise, and increase the service life of the chain. It is applied to the drive chain, belt or chain drive device and product transmission of almost every industry.

TGJJ-T-B

TGJJ-CT-B

TGJJ-TD-B

TGJJ-CTD-B

TGJJ-TT-B

TGJJ-TT-B

TGJJ-U-B

TGJJ-TU-B

TGJJ-TS-B

TGJJ-CTS-B

TGJJ-CTU-B

TGJJ-CU-B

TGJJ-K-B

TGJJ-CK-B

TGJJ-CKG-B

TGJJ-CKG14H-B

TGJJ-CKG15V-B

TGJJ-ETA-B

TGJJ-R-B

TGJJ-CRU-B

TGJJ-CRG-B

TGJJ-CRO-B

TGJJ-RR-B

TGJJ-RRC-B

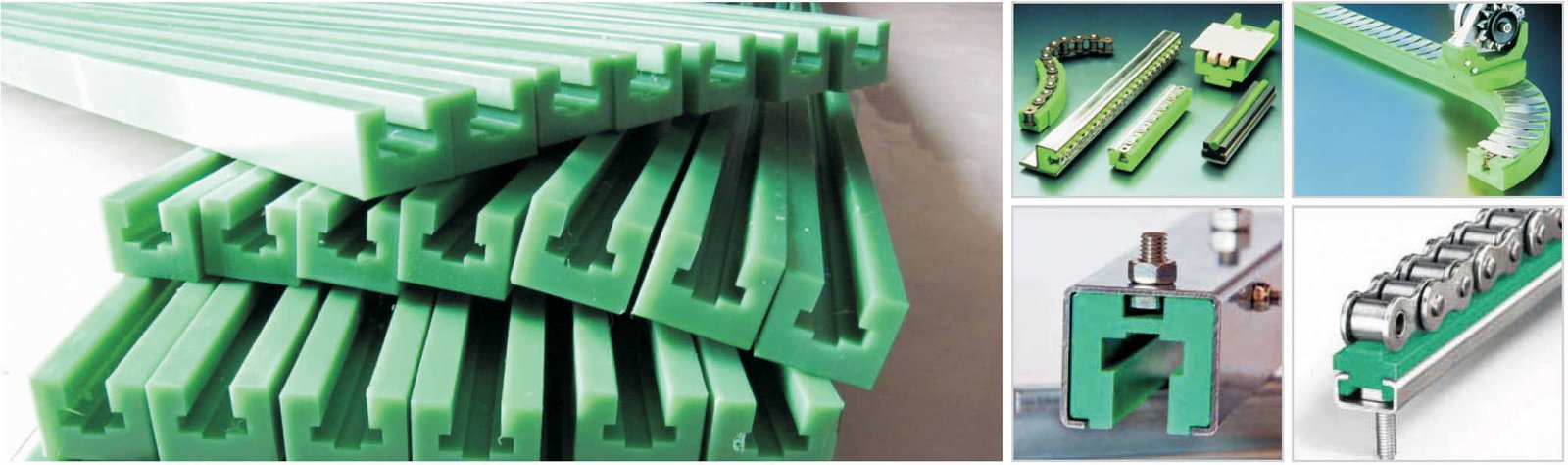

Gonow UHMW-PE Guide Rail

UHMWPE has many advantages such as exceellent physical and mechanical properties and wear resistance, self-lubrication, good sound-absorbing effect corrosion resistance, anti-adhesion, light weight and so on. lt has great advantages application mark ket in the packaging and food machinery industry.

We have successfully provided various types s of switches and structures, such as wear-resistant guardrails, pads, and chain guides to various conveyor lines.

Food industry Applications

In the food industry, UHMWPE profiles are applied for canned, bottled food delivery pipelines which not only makes transport smoothly but also prevents bottle collisions and greatly reduces noise. UHMWPE products are applied in the packaging lines of powdered foods, instant foods, and chocolates. The sliding properties and durability of the products are widely appreciated.

Your Reliable UHMW-PE Factory

Professional Engineer Teams and Sales Teams

Most of them have more than 10 years experienced in mold-making industry and injection industry, especially for medical, electronic and automotive products

Good After-Sale Service

We offer good service within 3 years after customer receive the products. Most of our customers work with us for long time and still trust, satisfy and do with us.

One-Stop Service

No matter design, material, semi-products such as sheets, rods, tubes and films, finished parts, quality control, we take care of every steps and you just relax and receive your products.

Advanced Equipments

We have the high quality 4-axis and 5-axis CNC and EDM machines to offer stable and accurate processing ability.

Fast Delivery Time

Our model workshop have two turns everyday, Our workes and engineer work for 8 hours. We can make a prototype mold within 20 days, and 30-35 days to make a complex mold.

High Quality and Factory Price

We have passed ISO, SGS, RoHS, FDA Certification. and we have Chinese Production Cost Control Experience. so we can help you save about 20%-30% manufacturing cost.

What Our Happy Clients Say?

Get A Qucik Quote?

Consult Your Engineering & High Perfomance Materials Expert

- Get Quote In 12 Hours

- 7/24 Online Service

- Free Sample Available

- info@gonowplastics.com